The SCOR model is the most widely recognised reference for supply chain processes for any supply chain professional. The emergence of new ways of doing business in the circular economy has been revised lately to the circular SCOR model.

What is a circular economy?

The transition from a linear model of take, make, and dispose and bending that line to a circle where waste becomes the input for what we make.

It is based on three principles:2

- Design out waste and pollution

- Keep products and materials in use

- Regenerate natural systems

Ellen MacArthur Foundation, one of the very prominent names in promoting “circular economy” defines the circular economy with a butterfly diagram to visualise this with two main cycles – the technical cycle and the biological cycle.

Technical Cycle: Things which does not biodegrade. Typically valuable and can be kept in circulation through reuse, repair, remanufacture and recycling.

Bio-degradable Cycle: Anything which is biodegradable. Which needs to go back to the soil.

Closed-loop supply chain: Returned to the same product. both forward and reverse networks are integrated within a centrally managed system. Eg: An empty glass bottle of coke that is collected and returned to Coca Cola’s sorting site with the help of its logistic partners through a customer deposit scheme.

Open-loop supply chain: Returned to the industry as a different reusable product

that deals with both forward and reverse flows of products, with the third parties (other than original manufacturers) responsible for reverse operations. Eg: An empty glass bottle of coke that is collected through recycling centres and remanufactured and reused by a different drinks company.

The benefit of a Circular Supply Chain:

Saves carbon emissions by avoiding material extraction

The major cause of global warming is Material extraction and creation. All the issues related to the supply chain faced today, like climate change, species reduction, and deforestation is all linked to the extraction of raw materials.

Even for an electric vehicle, the majority of emissions are in the extraction of Lithium, Nickel, and Cobalt which are typically the raw materials for batteries.

Cost

Money is one of the prime movers of the circular economy.

Remanufacturing components gives a financial saving of 40% and saves 80% of emissions. Remanufactured engines are 5 times less costly. The cost of remanufacturing a mobile phone could be reduced by 50% per device.

Important to avoid waste and also Reduce consumption.

Biggest hurdles: Why are linear Supply Chains still very popular?

From a consumer perspective, the idea of convenience, affordability and product range is benefits of a linear system which needs to be emulated in a circular economy.

The benefit of recycling is based on whether the waste management companies can make money by recycling. For eg. Aluminium since it’s highly valuable than the cost of collecting and processing however, 80% of materials are costly to collect and recycle waste.

Groups including Coca-Cola, PepsiCo, Nestlé, Keurig Dr Pepper and Danone are all targeting at least 25 per cent or more post-consumer recycled content in their packaging by 2025, a target mandated for bottles by the EU

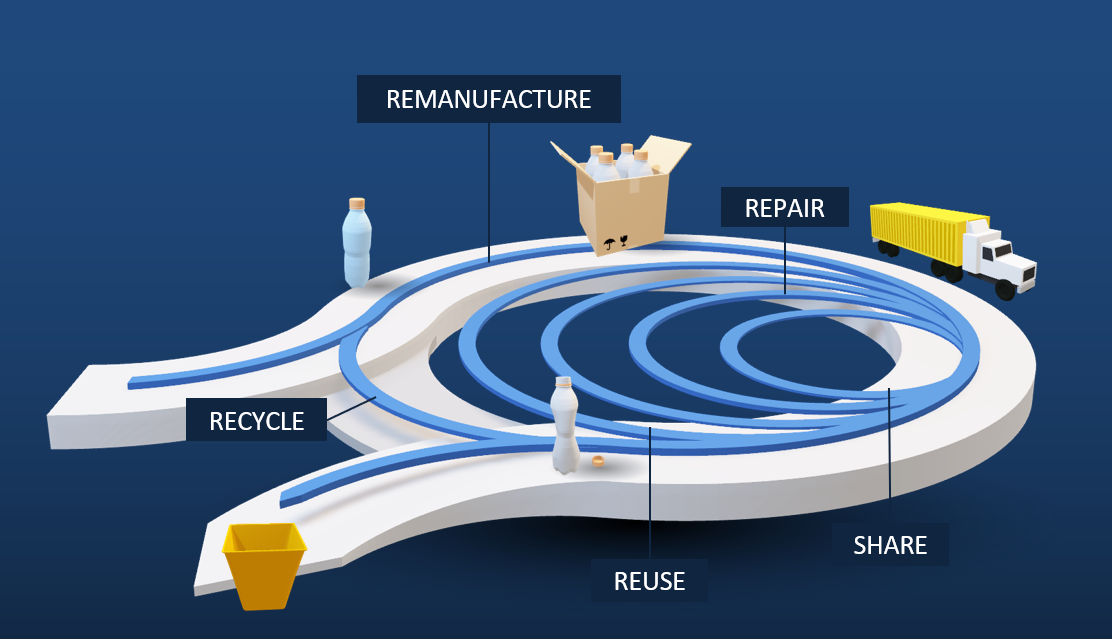

How to go to tighter circles?

From a Recyclable base circular economy, use based circular economy does less work for recycling.

Designing a Circular Supply Chain design

We see three ways businesses can start:

(1) They all implemented modular product architectures;

(2) they leased, instead of selling, at least some of their products; and

(3) they expanded their refurbishing operations.

We focus on improving or rethinking products and processes for a circular model rather than setting up a circular economy business (such as a specialist recycler or reseller). We begin with product design, as this informs many other aspects.

Reuse: Brands to produce a reusable version of products.

Garment or bottle A bottle of Coca Cola: If it moves(Linear) being owned to borrowed(circular) by the consumer. So the consumer pays for the use of the product rather than the entire item.

Average Rating